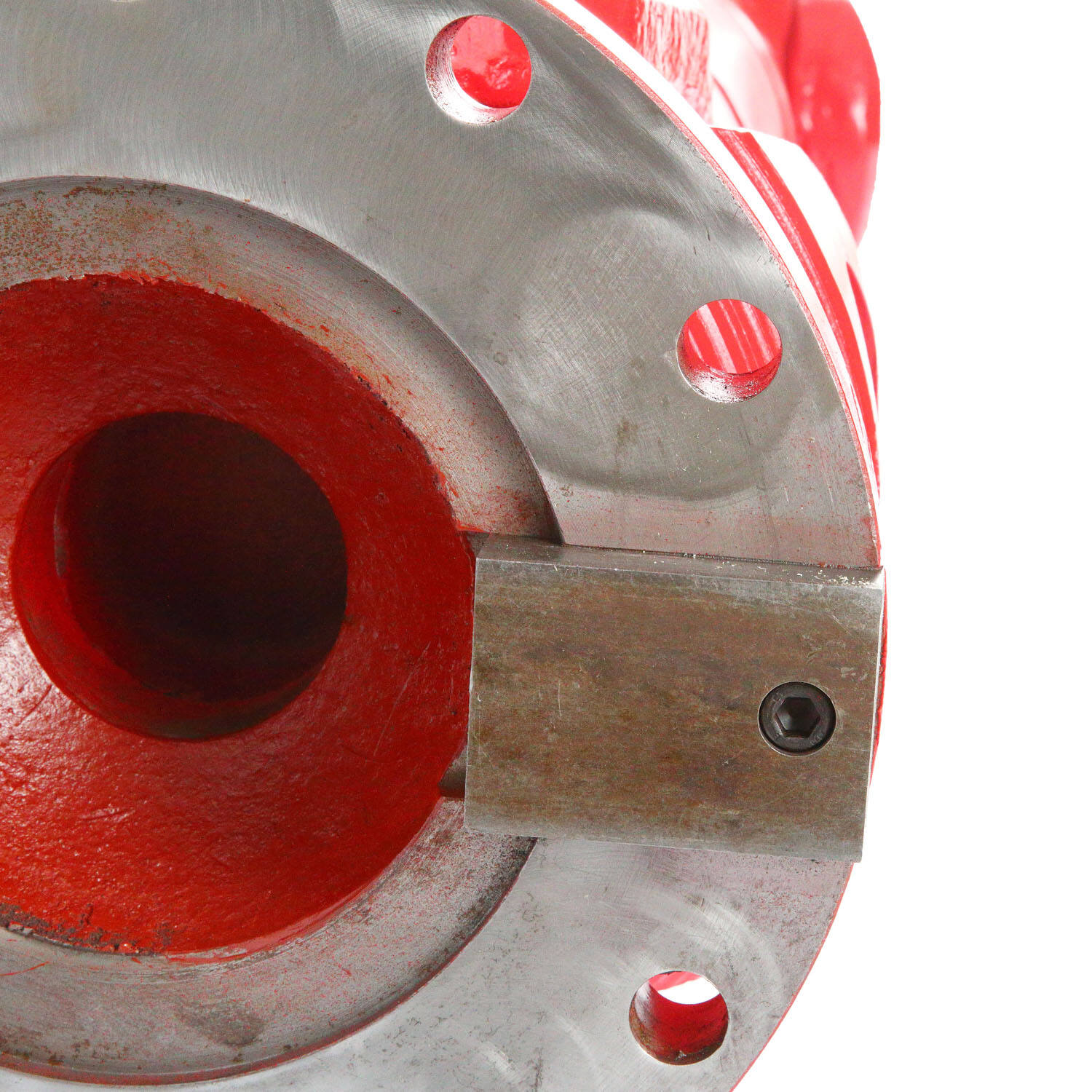

double cardan shaft

A double cardan shaft, also known as a double universal joint shaft, represents a sophisticated mechanical component designed to transmit rotational power between two non-aligned shafts while maintaining constant velocity. This innovative system consists of two universal joints connected by an intermediate shaft, working in tandem to eliminate the speed fluctuations typically associated with single universal joints. The unique design allows for operation at higher angles, typically up to 45 degrees, making it ideal for applications where significant misalignment between input and output shafts exists. The double cardan configuration ensures smooth power transmission by canceling out the periodic velocity variations inherent in single universal joints. This is achieved through precise geometric arrangement, where the second joint is positioned to counteract the angular velocity fluctuations produced by the first joint. The system finds extensive use in various industrial applications, including automotive drivelines, heavy machinery, and manufacturing equipment where reliable power transmission under challenging angular conditions is essential. The shaft's robust construction typically incorporates high-grade steel components, precision bearings, and specialized lubricants to ensure durability and optimal performance under demanding conditions.