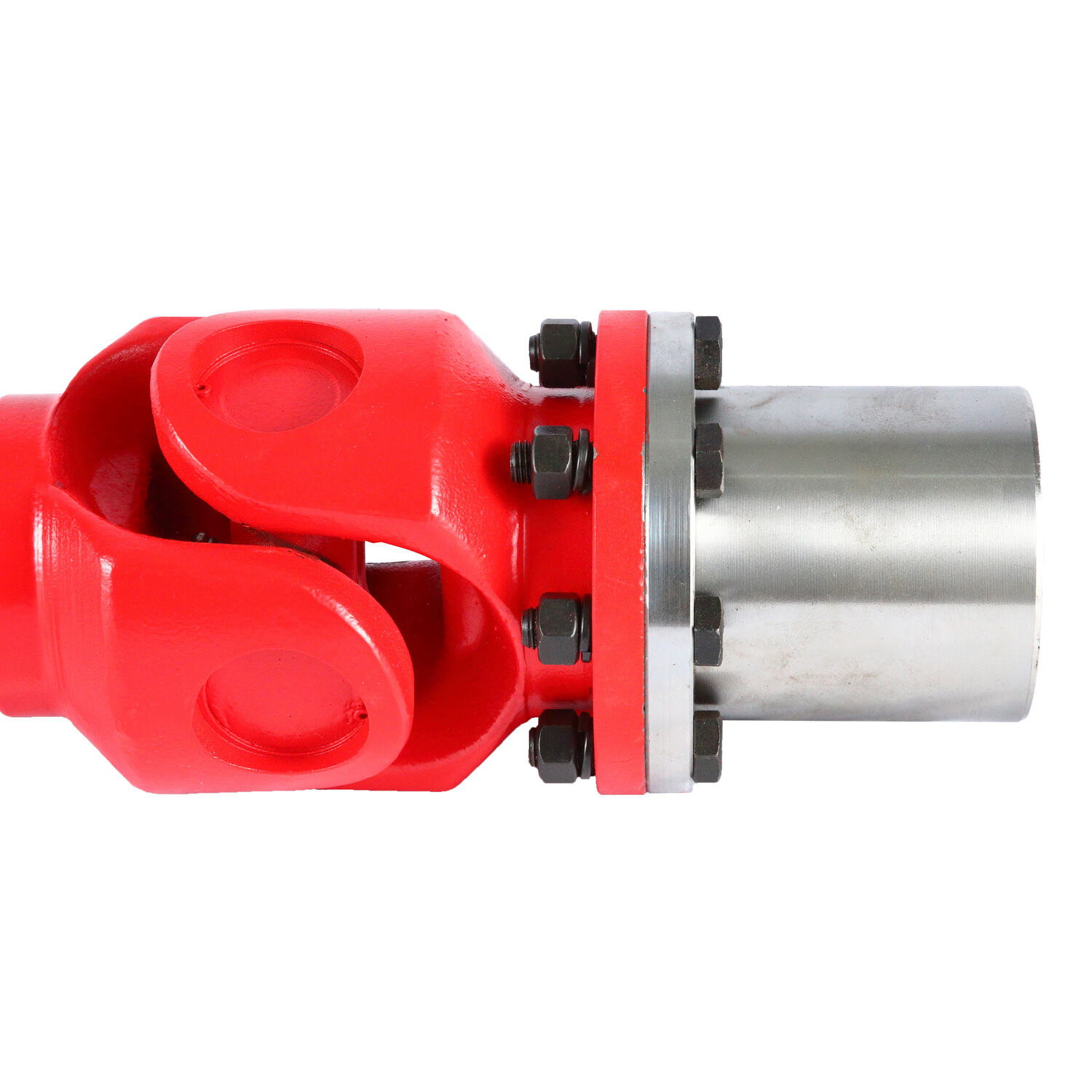

dual cardan style driveshaft

A dual cardan style driveshaft represents a sophisticated power transmission component that employs two universal joints configured in a specialized arrangement to deliver smooth and efficient power transfer between the transmission and differential. This innovative design effectively manages angular misalignment while maintaining constant velocity output, making it particularly valuable in vehicles with significant suspension travel or altered ride heights. The shaft's construction typically features high-strength steel or aluminum components, precision-engineered U-joints, and carefully balanced assemblies to minimize vibration and ensure optimal performance. The dual cardan configuration allows for greater articulation angles compared to single-joint designs, typically accommodating up to 30 degrees of angular displacement without compromising performance. This capability makes it especially suitable for lifted trucks, off-road vehicles, and custom automotive applications where standard driveshafts might face limitations. The system's design also incorporates advanced needle bearing assemblies and high-grade lubricants to ensure longevity and reliability under demanding conditions.