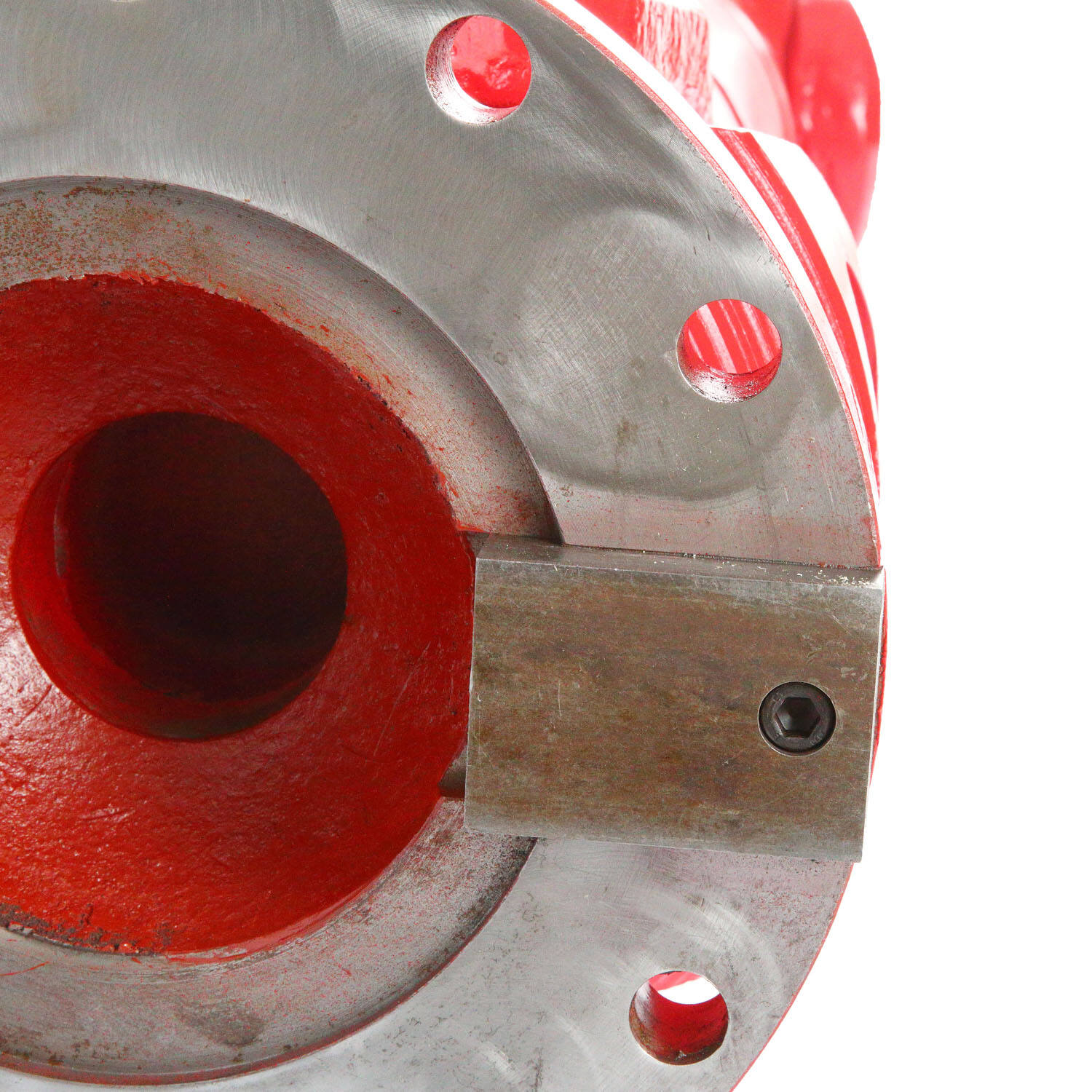

tyre type coupling

A tyre type coupling is an essential mechanical component designed to connect two shafts while accommodating misalignment and reducing vibration transmission. This coupling consists of a flexible rubber element sandwiched between two metal hubs, creating a reliable connection that can handle various industrial applications. The rubber element is manufactured from high-quality elastomeric materials, specifically engineered to withstand harsh operating conditions and provide excellent torsional flexibility. The design allows for angular, parallel, and axial misalignment between connected shafts, making it particularly valuable in applications where perfect alignment is challenging to maintain. The coupling's construction enables it to absorb shock loads and dampen vibrations effectively, protecting connected equipment from potential damage. These couplings are widely used in industrial machinery, pumps, compressors, and various power transmission applications. The tyre type coupling's ability to operate without lubrication, combined with its minimal maintenance requirements, makes it a cost-effective solution for many industrial applications. The coupling's design also incorporates features that ensure easy installation and replacement of the flexible element when necessary, reducing downtime and maintenance costs.