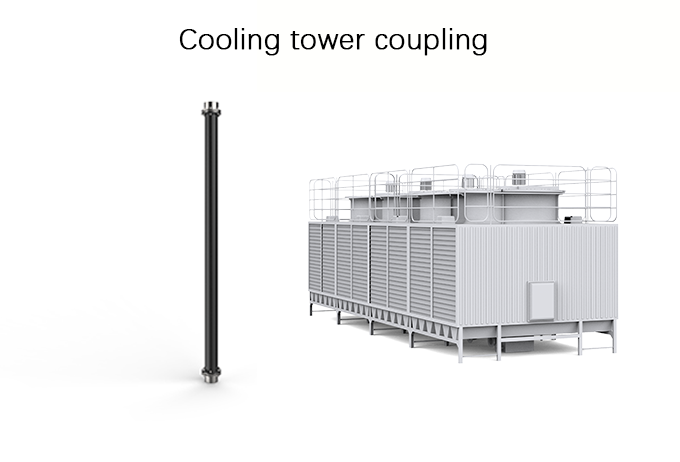

universal flange coupling

The universal flange coupling represents a crucial mechanical component designed to connect two rotating shafts, enabling power transmission while accommodating misalignment. This versatile coupling consists of two flanged hubs connected by a flexible element, typically featuring multiple bolts arranged in a circular pattern. The design allows for angular, parallel, and axial misalignment between connected shafts, making it highly adaptable to various industrial applications. Universal flange couplings are engineered with precision to ensure smooth torque transmission while minimizing vibration and mechanical stress. The coupling's construction typically incorporates high-grade materials such as steel or cast iron, offering excellent durability and resistance to wear. One of its distinguishing features is the ability to operate effectively across a wide range of speeds and loads, making it suitable for both light-duty and heavy-duty applications. The coupling's design also facilitates easy installation and maintenance, with removable components that allow for quick inspection and replacement when necessary. In industrial settings, these couplings are commonly found in pumps, compressors, generators, and various types of manufacturing equipment where reliable power transmission is essential.