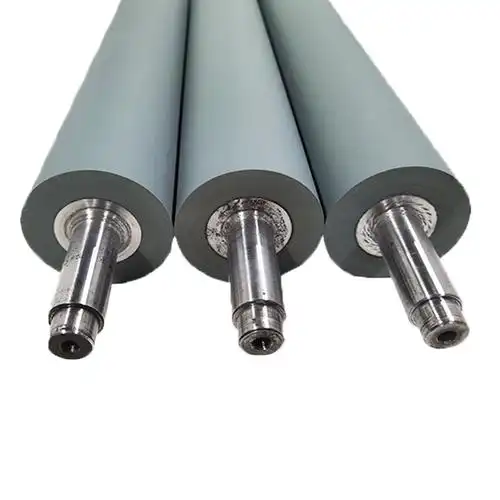

rubber pressure roller

The rubber pressure roller is a crucial industrial component designed to apply consistent pressure across various materials during manufacturing processes. These precision-engineered cylinders combine a robust metal core with a specialized rubber coating, offering both durability and flexibility in operation. The roller's primary function is to maintain uniform pressure distribution, essential for processes such as laminating, printing, and material handling. The rubber coating's hardness can be customized, typically ranging from 20 to 90 Shore A, to meet specific application requirements. Advanced manufacturing techniques ensure precise dimensional tolerance and concentricity, while the rubber compound selection offers resistance to wear, chemicals, and temperature variations. These rollers feature precision-ground surfaces for optimal contact and pressure distribution, making them indispensable in industries ranging from paper processing to textile manufacturing. Modern rubber pressure rollers often incorporate innovative features such as static dissipation properties and specialized surface patterns for enhanced grip and material handling capabilities.