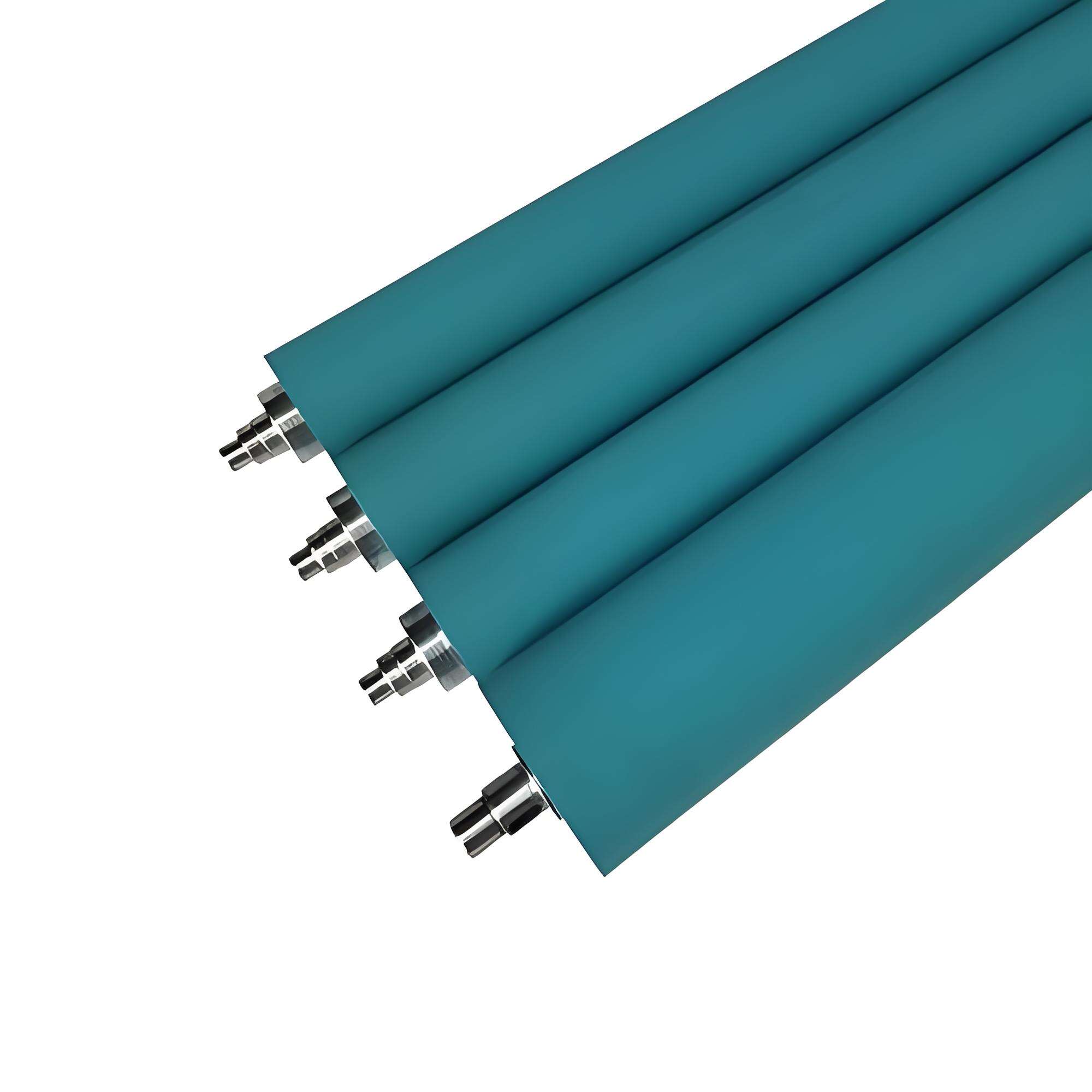

rubber roller bearing

A rubber roller bearing is an innovative engineering component that combines the durability of traditional bearings with the versatility of rubber elements. This specialized bearing consists of a rubber-coated roller element that operates within an outer race, providing unique performance characteristics. The rubber coating acts as a cushioning layer, effectively absorbing vibrations and reducing noise during operation. The design incorporates precision-engineered rubber compounds that are bonded to metal cores, ensuring optimal performance across various operating conditions. These bearings excel in applications requiring both rotational movement and vibration dampening capabilities. The rubber element's resilient nature allows for slight misalignment tolerance while maintaining smooth operation, making it particularly valuable in industrial machinery, conveyor systems, and automotive applications. The bearing's construction allows for effective load distribution while minimizing wear on connected components. Its self-lubricating properties, derived from the rubber compound's characteristics, reduce maintenance requirements and extend operational life. The unique combination of rubber and metal components creates a bearing solution that bridges the gap between traditional rigid bearings and flexible mounting systems.