Abstract: Water, lubricating grease and oxidised iron filings can easily cause damage to the spline shaft and cross bearing of the cardan shaft, our company upgrades and improves this, and prolongs the service life of the cardan shaft by adding the protective measure of rubber sheath.

Content:

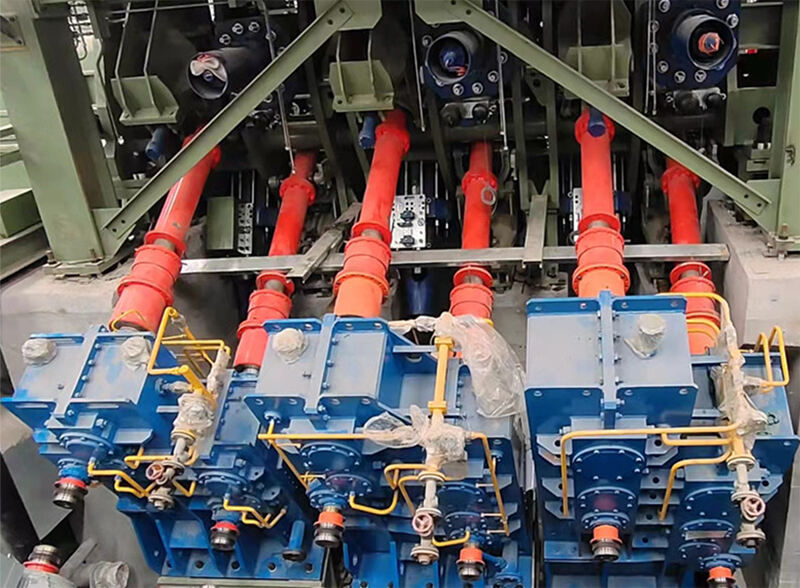

The pinch roll device of continuous rolling production line of large foreign steel mills consists of upper and lower two roll devices, which are driven by electric motor through reducer and cardan shaft respectively. In the normal operation of the equipment, the front pinch feed rolls are pressed by cylinders, which have good impact resistance. In the finishing mill failure, the front pinch rolls can be pressed by the hydraulic cylinder with large pressure to pull the strip out of the finishing mill function in reverse; at the same time, the front pinch rolls also have the function of closing the high-pressure water, which is safe and reliable. In the use of the cross bearing and spline damage, our company according to customer feedback, after in-depth technical communication, decided to use the addition of rubber sheath to solve the customer's problem, to extend the service life of the universal axis.

|

|

|

After the technical analysis of both sides, due to the high-pressure water overflowed from the window of the pinch roller, which washed the part of the cross shaft, the water contained iron oxide chips, the water immersed in the cross bearing and spline shaft emulsified the lubricating grease and took away the grease, which resulted in the loss of lubricating grease, and the water brought the iron oxide chips into the bearing at the same time, which deteriorated the bearing's working conditions, and the above problems were the main reasons for the damage of the cardan shaft.

Modification programme: install rubber sheath on the cardan shaft and lock it by adding clamps at both ends, the rubber sheath rotates with the cardan shaft to solve the problem of water and iron oxide chips intrusion.

Effect:

1, can effectively extend the service life of the cardan shaft;

2、Reduce the daily maintenance of the cardan shaft, reduce the maintenance cost;

3, rubber sheath structure is simple, easy to install;

Can promote the use of rolling mills often appear similar situations, such as in the same working environment, the use of dental coupling coupling transmission equipment, can also be used;