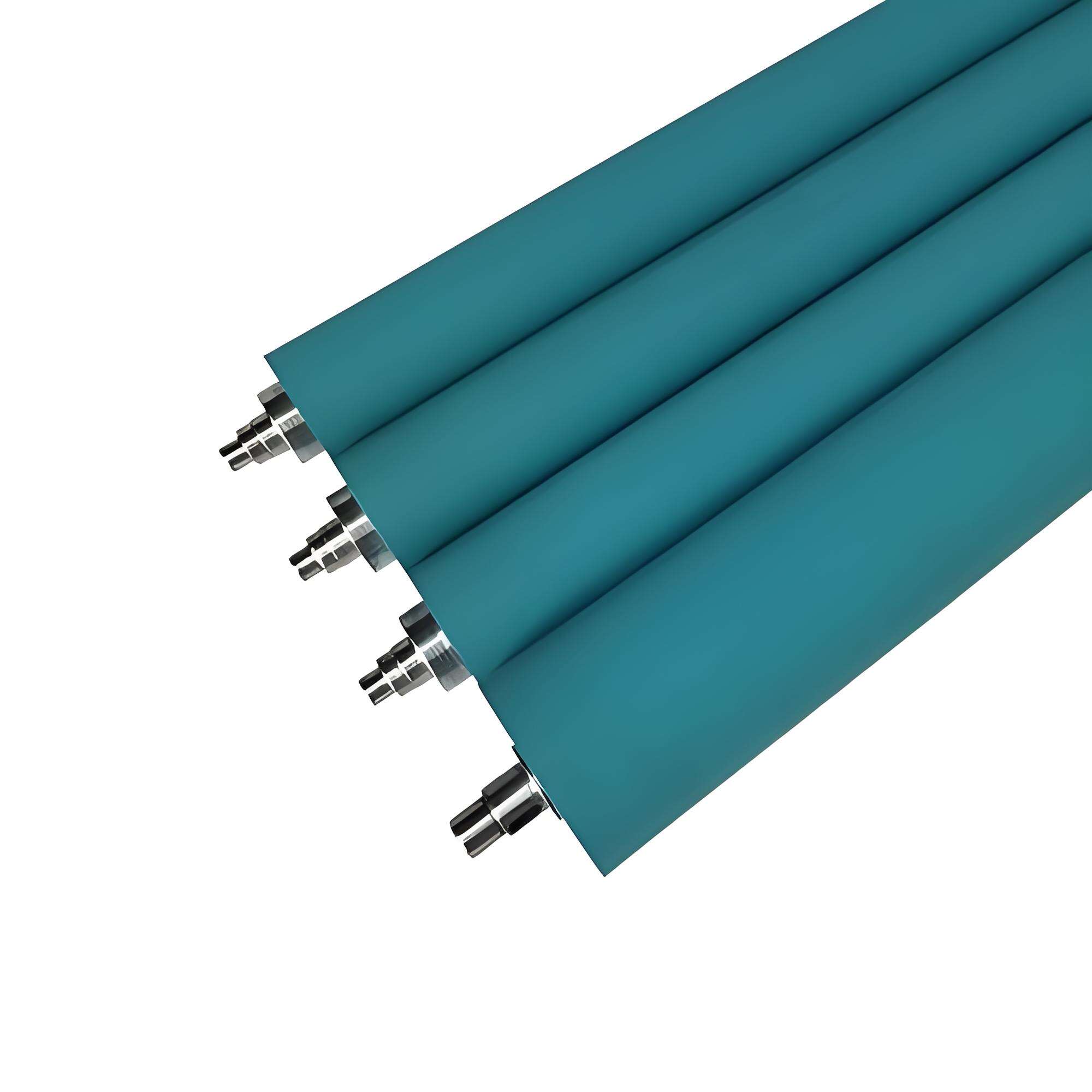

rubber coated rollers

Rubber coated rollers represent a crucial component in various industrial applications, combining durability with precision engineering. These specialized cylinders feature a robust metal core encased in high-quality rubber compounds, designed to meet specific operational requirements. The rubber coating can vary in thickness, hardness, and chemical composition, allowing for customization based on intended use. These rollers excel in applications requiring precise material handling, pressure distribution, and surface contact control. Their design incorporates advanced vulcanization processes that ensure optimal bonding between the rubber coating and metal core, preventing delamination under stress. The rollers can be manufactured with different surface patterns and textures, enabling enhanced grip, material transport, or specific processing requirements. They play vital roles in printing, paper processing, textile manufacturing, and conveyor systems. The rubber composition can be engineered to resist wear, chemicals, heat, and environmental factors, ensuring longevity in demanding industrial environments. Modern rubber coated rollers often incorporate precision balancing and specialized coating technologies to maintain consistent performance at various operational speeds. Their design considers factors such as load bearing capacity, nip pressure requirements, and specific industry compliance standards.