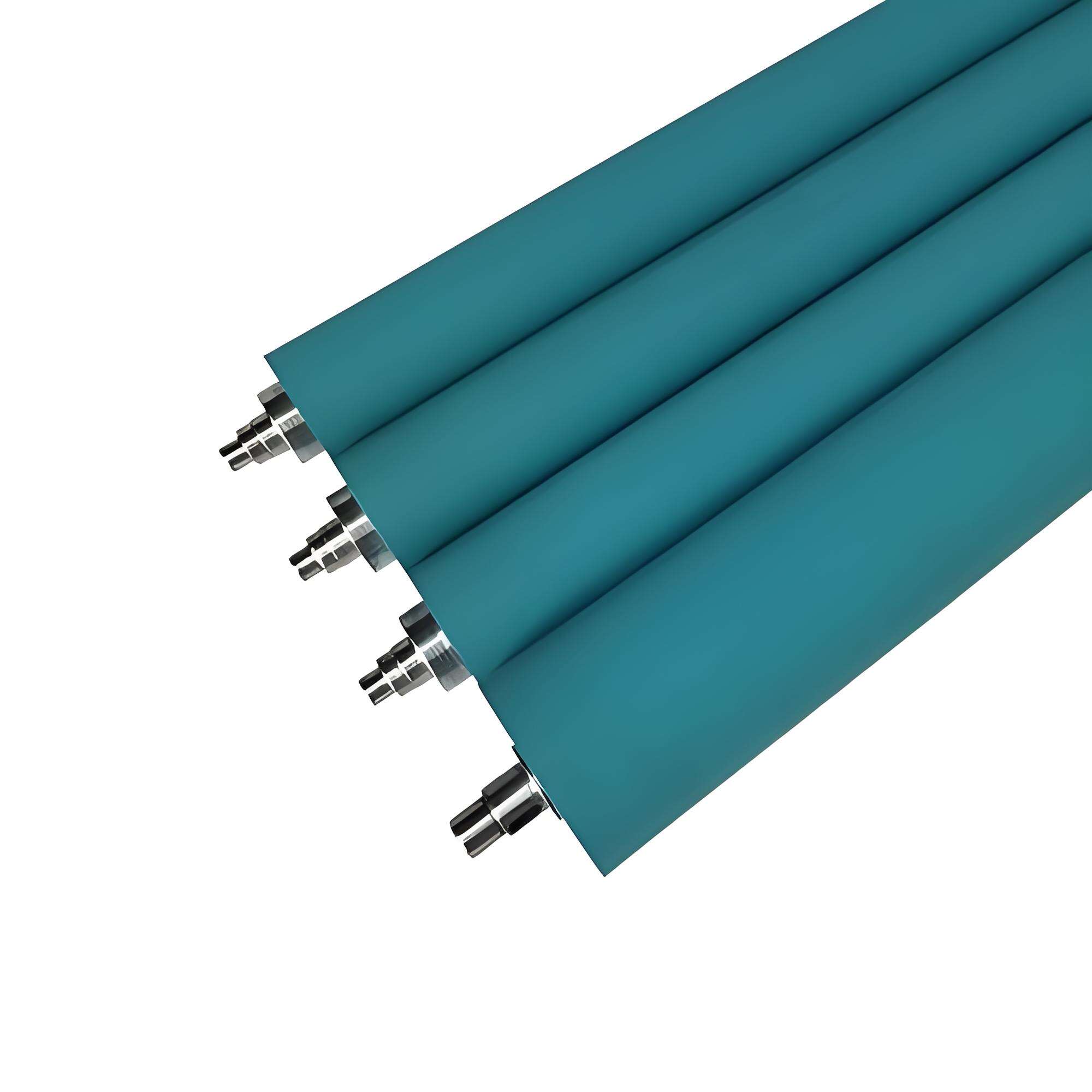

silicone rubber roller

A silicone rubber roller represents a crucial component in various industrial applications, combining durability with exceptional performance characteristics. These precision-engineered cylinders feature a core typically made of aluminum or steel, encased in a specially formulated silicone rubber compound. The unique properties of silicone rubber, including its temperature resistance ranging from -60°C to 200°C, make these rollers indispensable in numerous manufacturing processes. The surface characteristics can be customized with varying hardness levels, typically ranging from 20 to 80 Shore A, to meet specific application requirements. These rollers excel in applications requiring precise material handling, consistent pressure distribution, and reliable performance under challenging conditions. Their non-stick properties and resistance to chemical degradation make them particularly valuable in printing, laminating, and converting operations. The silicone rubber composition ensures excellent release properties, preventing material adhesion while maintaining consistent surface quality throughout extended operational periods. Modern manufacturing techniques allow for precise dimensional control and surface finishing, enabling these rollers to deliver superior performance in high-precision applications.