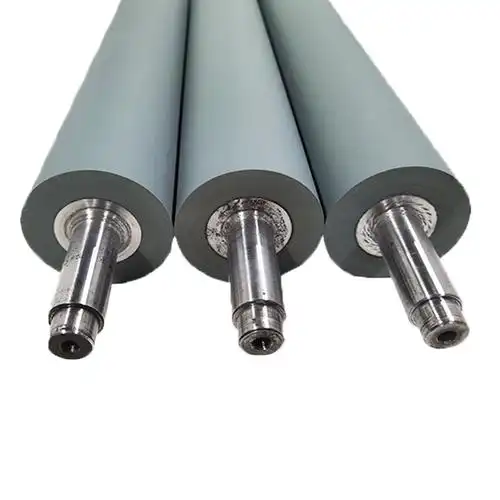

small rubber roller

The small rubber roller is a versatile industrial component designed for precise material handling and transfer applications. This compact yet robust device features a cylindrical rubber surface mounted on a metal core, engineered to provide consistent performance in various operational environments. The roller's design incorporates specific durometer ratings to ensure optimal grip and pressure distribution, making it ideal for conveyor systems, printing processes, and material processing applications. The rubber compound used in these rollers is carefully selected to resist wear, chemicals, and environmental factors while maintaining its essential mechanical properties. Available in multiple diameters and lengths, these rollers can be customized to meet specific application requirements, offering flexibility in installation and maintenance. The engineering behind these rollers focuses on achieving uniform surface characteristics, ensuring even pressure distribution and consistent material handling across the entire roller length. Advanced manufacturing techniques guarantee precise concentricity and balance, which are crucial for smooth operation and extended service life. The small rubber roller's design also incorporates features for easy mounting and replacement, minimizing maintenance downtime and operational disruptions.